This page addresses rough threads or cross-threading. This could be due to a spindle encoder problem or a Z axis mechanical issue. For thread-fit issues, see Size-holding Issues.

Here are diagnostics for spindle and mechanical tests for cross-threading:

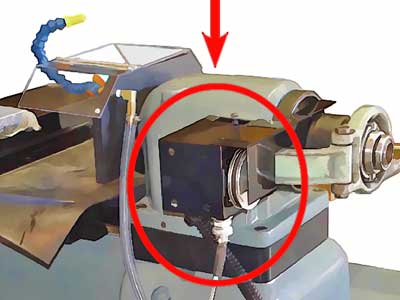

Spindle encoder test:

NOTE: If your OmniTurn has belt-driven encoder (GT series: Belt-driven encoder on GT pre-2006; Attachments:

Belt-driven encoder on GT pre-2006; Attachments: Belt-driven encoder on Attachment pre-2010, first make sure the belt and pulleys appear to be in good condition, and that the pulleys aren't loose on the spindle or encoder. Detailed instructions for checking for belt or pulley slippiage can be found at G3 CNC Threading Issues.

Belt-driven encoder on Attachment pre-2010, first make sure the belt and pulleys appear to be in good condition, and that the pulleys aren't loose on the spindle or encoder. Detailed instructions for checking for belt or pulley slippiage can be found at G3 CNC Threading Issues.

- In Jog mode, press Ctrl-S. An asterisk should pop up next to the RPM readout on the screen. When the asterisk is there it indicates that the display is reporting the spindle position instead of RPM.

- Rotate the spindle by hand, and the display should count up to 3999 and then roll over to 0.

- Run the spindle at top speed, and watch the spindle position indicator. The numbers will change too fast for you to track, but if the counter fails to roll over the display will freeze at 9999 and go to dark lettering on a white background, indicating a count error.

- If you don't see that 9999, shut the spindle off and rotate it again by hand, finding the point where the count rolls over from 3999 to 0.

- Make a mark on the spindle at that point and then run the spindle at top speed for awhile (a couple of minutes or so) again.

- Shut it down again and rotate it by hand back to the point where the count rolls over from 3999 to 0.

- If your witness mark is no longer lined up at that point, the mechanical relationship between the motor/encoder and the actual spindle has changed.

- With belt driven encoders, the encoder belt/pulley is most likely your culprit.

- With motor-mounted encoders or c axis machines it would almost have to be the spindle drive belt somehow skipping teeth.

- If the witness mark is still lined up with the counter rollover, the threading problem may be due to mechanical issue in Z-axis.

Mechanical Test:

- Set up an indicator to measure motion along the Z-axis, with a mag base on the tooling plate and the indicator against the spindle nose or headstock.

- With the servos on, get hold of a tool block and push and pull the axis along the direction of the axis. You should see some deflection on the indicator when you are applying pressure, but when you release it it should spring back to where it started.

- If the indicator does not spring back (ie shows some looseness), you can expect to see at least the indicated amount of roughness on your threads.