This page addresses rough threads or cross-threading. This could be due to a spindle encoder problem or a Z axis mechanical issue. For thread-fit issues, see Size-holding Issues.

Here are diagnostics for spindle and mechanical tests for cross-threading:

Belt or Pulley Slippage

If your OmniTurn has belt-driven encoder ( pre-2006; pre-2010) the cross-threading may be caused by belt or pulley slippage. Here is a procedure for determining if the bad threads are caused by belt or pully slippage:

Preparation:

- In jog mode, move the X and Z axes away from their home positions by .1" or so, then shut the servos off by pressing the E-stop button on the front of the control.

- Unplug the X motor from its socket at the back of the control and plug the spindle encoder cable into the X motor socket.

Finding the Index position:

- Turn the servos back on and press #9, then Cycle Start.

- The "Z REFERENCE IN PROGRESS" message should come up, and when Z has finished homing, the "X REFERENCE IN PROGRESS" message should appear.

- Slowly rotate the spindle by hand while watching the screen.

- When the "X REFERENCE IN PROGRESS" message goes away, the index position has been reached.

- Press Ctrl-E to bring up the following error display. Each count of following error for the X axis is 1 spindle encoder count (1/4000 of a revolution) away from the spindle index position.

- Rotate the spindle to get the X following error to 0, and make a line from the face of the spindle across to the ring that surrounds it. You probably won't be able to get the spindle to sit right at 0, but get as close as you can and make a note of the following error reading when your marks are perfectly aligned.

- Shut the servos off again and put the spindle encoder and X axis cables back where they belong.

Testing:

- Home the machine correctly and go into Manual Data Input mode and run the spindle at 4000 RPM for 5 minutes or so.

- Find the index position again after running the spindle for awhile.

- When you rotate the spindle to the following error reading you noted the first time, your scribe marks should be perfectly aligned.

- If they are not, your encoder timing belt has skipped, or one of the pulleys have slipped on its shaft. This could be due to a bad belt, worn pulleys, or just debris in the teeth of the pulleys or belt. Note: each tooth=33 encoder counts (120 teeth).

Mechanical Test:

- Set up an indicator to measure motion along the Z-axis, with a mag base on the tooling plate and the indicator against the spindle nose or headstock.

- With the servos on, get hold of a tool block and push and pull the axis along the direction of the axis. You should see some deflection on the indicator when you are applying pressure, but when you release it it should spring back to where it started.

- If the indicator does not spring back (ie shows some looseness), you can expect to see at least the indicated amount of roughness on your threads.

The Oregon Coast to show picture; click anywhere else to hide picture (Apple IOS: refresh page).

The Oregon Coast to show picture; click anywhere else to hide picture (Apple IOS: refresh page). The Oregon Coast to show picture; click anywhere else to hide picture (Apple IOS: refresh page).

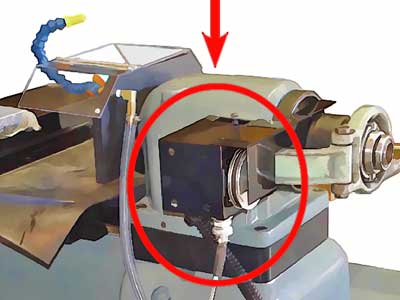

The Oregon Coast to show picture; click anywhere else to hide picture (Apple IOS: refresh page). Belt-driven encoder on GT pre-2006; Attachments:

Belt-driven encoder on GT pre-2006; Attachments: Belt-driven encoder on Attachment pre-2010) the cross-threading may be caused by belt or pulley slippage. Here is a procedure for determining if the bad threads are caused by belt or pully slippage:

Belt-driven encoder on Attachment pre-2010) the cross-threading may be caused by belt or pulley slippage. Here is a procedure for determining if the bad threads are caused by belt or pully slippage: