OmniTurn CNC Lathes Made in Oregon

The World’s Most Cost-Effective Turning Machines

OmniTurn ZipLoader Parts

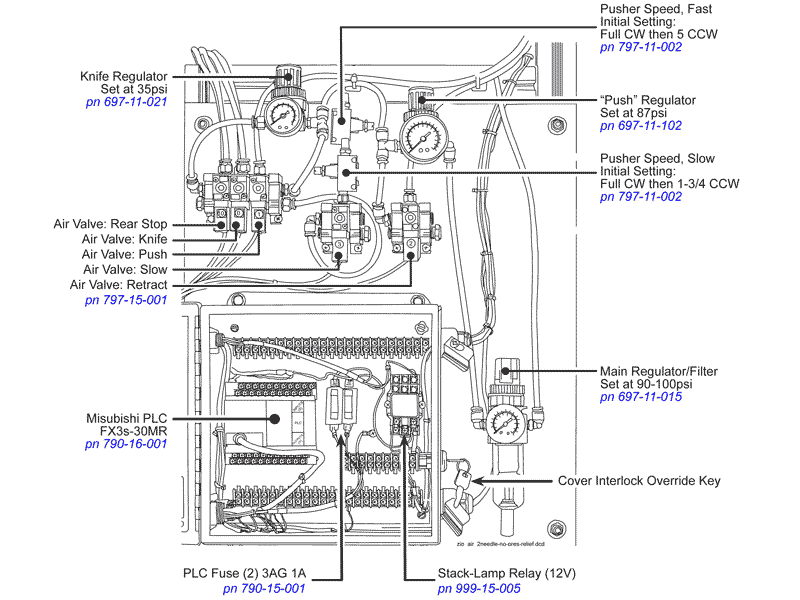

The current air panel is shown directly below. The air solenoids, regulators, flow-control, pressure relief valve and PLC cabinet are mounted to this panel.

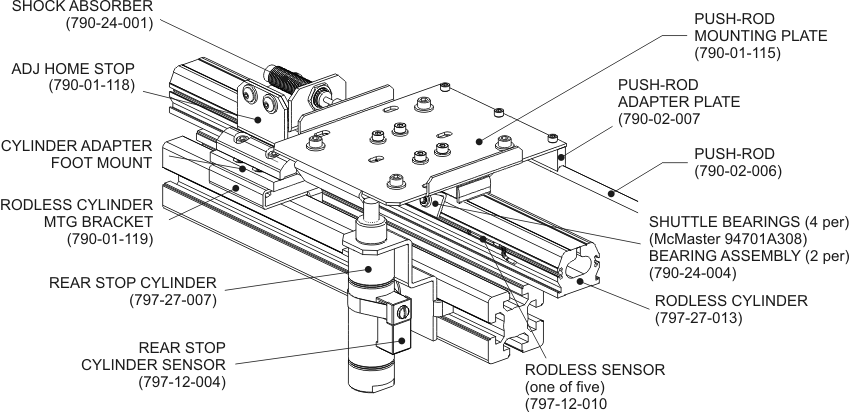

Pusher component parts are shown directly below. All components associated with the shuttle are shown, including the rear-stop cylinder assembly, which is used with the table-stop, to provide a means for trimming parts to overall length.

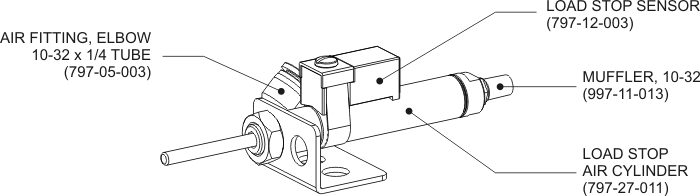

Knife cylinder component parts are shown directly below. "Knife up" and "knife down" sensors are shown.

The spring-loaded stop is shown directly below. This assembly is stored in the PLC cabinet. Use it with Rear Stop to qualify parts to overall length. See "Operation & Programming" document for more information. When trimming parts to overall length, this assembly is mounted on the OmniTurn tooling plate (table)..