Automatic bar loader!

Loads bar for machining and cutoff; pushes more bar for next part.

At end of bar, ZipLoader ejects remnant and loads new bar.

Tray holds 40 half inch bars for hours of un-attended operation.

Automatic shaft loader!

Loads part for machining and locks it in collet.

Then it ejects finished part, gets next part.

Handles bars or parts from 1-1/2 to 26 inches long, from 0.090″ to 1 inch diameter.* Optional parts hopper available.

*0.090″ requires optional thin escapement

- Fast

- Unloads finished 6" long part and loads next part in less than four seconds.

- Ejects remnant and loads new 24" bar in ten seconds.

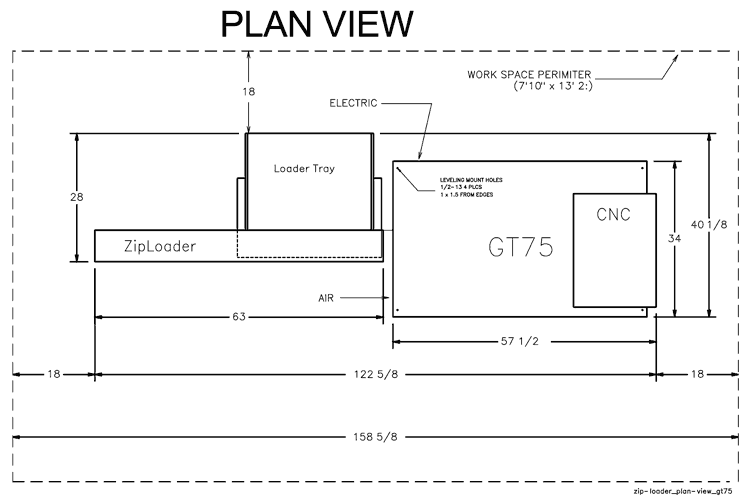

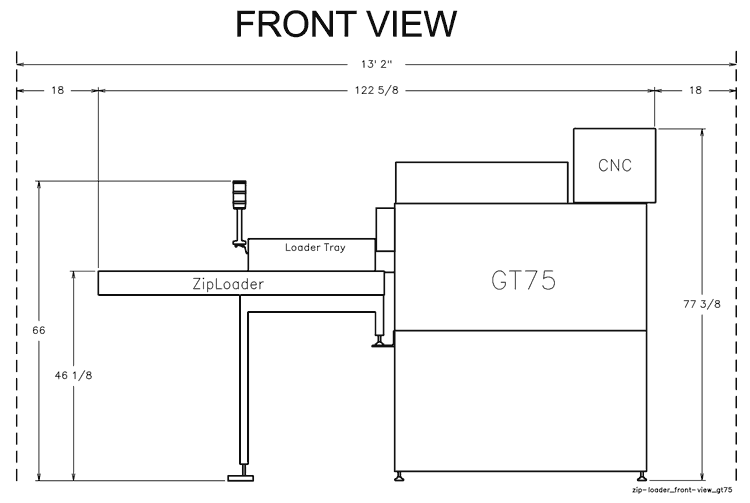

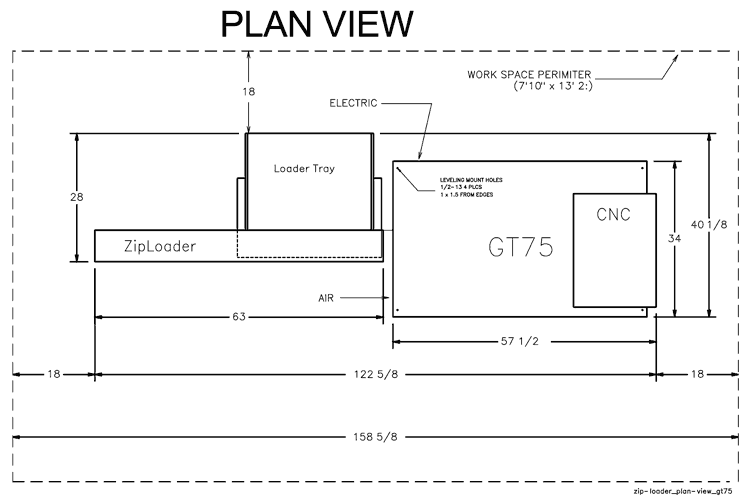

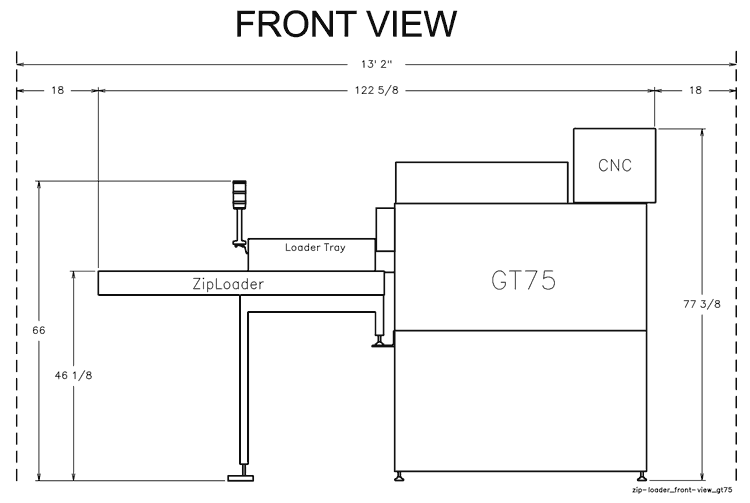

- Compact

- Adds only about 5 feet to overall length, but provides equivalent 20 feet of 1/2" bar.

- Width of loader is 30 inches.

- Versatile

- Loads bars or parts 1‑1/2 to 25" long.

- Handles parts 0.090" to 1‑1/8 diameter.

- Rear‑qualify feature provides ±0.002″ overall length accuracy.

Hex Bar Stock

Hex Bar Stock

Video shows hex bar job. 5/8 " hex barstock. Drill and tap 3/8-16 1-1/2" deep, then back-turn 9/16" at center of part. After machining, part-off into optional part catcher. 36 second cycle time.

Fast Shaft Loader: 6 second unload / load

Fast Shaft Loader

In this video we are putting a diamond knurl on a 5-5/8" x 0.168 thin-wall stainless steel tube. The tubes are loaded into a hopper on the auto-loader, which feeds them into the OmniTurn for knurling. After the knurling, the auto-loader ejects the finished part into an unloader, which transfers the part to a conveyor. The entire cycle takes about nine seconds, so we're knurling about 400 parts per hour.

Rear-qualify feature: trim parts to length ±0.002″

Rear Qualify

Video shows one inch long cylinders escaped from optional hopper onto ZipLoader infeed "vee". The cylinders are then trimmed to length ±0.002″. The overall length is established by a hard stop on the rodless cylinder body, and a spring-loaded stop on the OmniTurn tooling plate. The rodless cylinder stops against the shot-pin, and the spring-loaded stop holds the part against the pusher.