|

|

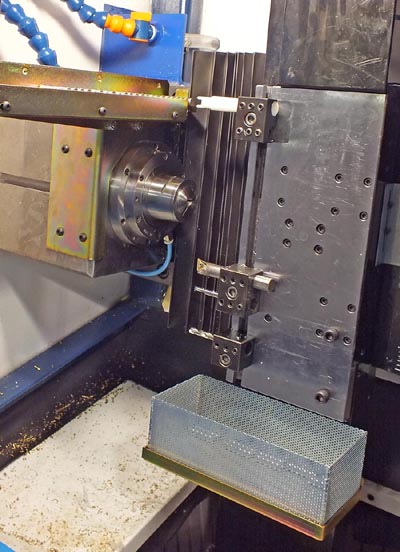

Eject parts to basket or conveyor

This track-loader is especially useful for complex parts with relatively long cycle-times. Parts are gravity-fed to a stop; a delrin pickup mounted on the tooling plate transfers each part from track to collet. The finished part is ejected by spring-loaded collet or by through-spindle coolant or air-blast. A basket mounted below the tooling plate catches the finished parts. Parts can also be ejected onto a diverter chute that delivers them to a conveyor which moves the parts out of the machine.

Handles wide range of parts

Parts can range from 1/4" or less to about 1-1/8" in diameter, and from about 1/2" long to about 1-5/8" long. Parts that are gripped on the od must have a length to diameter ratio of at least about 3:1 because the end of the part must project sufficiently for the pickup to grip it securely. Parts held on the id, or parts picked up by vacuum can be shorter than their diameter.

Pickup Tool and Collet Configuration

OmniTurn application technicians will work with you to design and fab a pickup suitable for your part. If your part requires qualification from the rear or from an existing feature, the pickup and collet configuration will be designed to meet this requirement. Mechanical drawings of the pickup and collet configuration will be provided with the track-loader.