Secondary offsets are tool offsets that can be applied to specific moves.

| XnZnDn: | On this move, tool #n will be offset by amount in secondary offset table. |

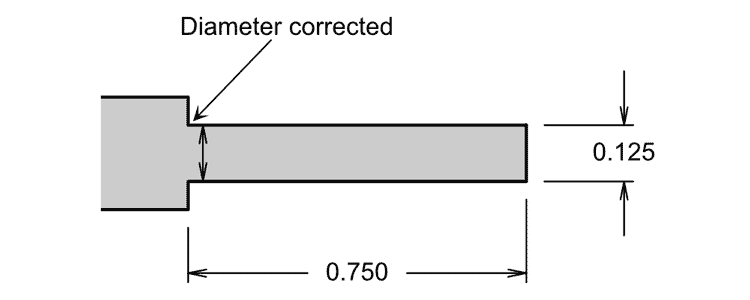

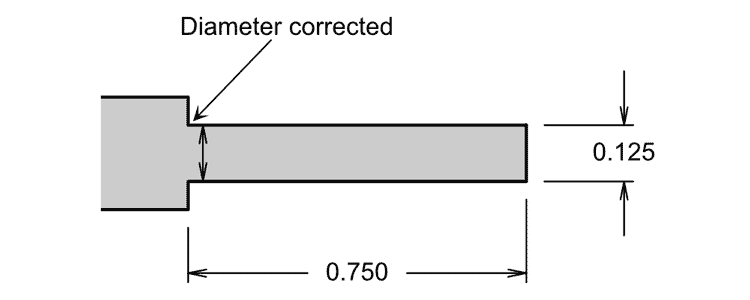

Here's an example part with potential taper in the 0.125 diameter:

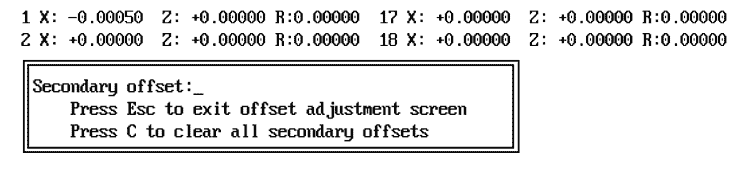

To adjust for the taper, call up the Secondary Offsets Table by pressing F9 in Auto Mode. Select the offset number you want to use (the offset # is independent of the tool#).

Shown below is an excerpt of the Secondary Offset Table with the X adjustment entered.

In this case Offset #1 is used, adjusting X to be -0.001 on the diameter. Note that the displayed value is radius:

The program would be:

| g90g72g94f300 | (header) |

| t2 | (lh turning tool) |

| x0z.1 | (starting point) |

| m03s2000 | (set spindle on, 2000 rpm) |

| g95f.003 | (feed 0.003 ipr) |

| z0 | (move to z0) |

| x.125 | (move to the diameter) |

| z-.75d1 | (turn diameter, correcting for taper) |

| x.2d0 | (next diameter; turn off offset) |

| z-.95 | (turn diameter) |

| x.21 | (clear part) |

| g00z.1 | (back to start) |

| m30 | (program end) |

The OmniTurn will re-interpret the line "z-.75d1" as "z-.75x0.1245", reducing the diameter by 0.001 as the tool moves toward Z-0.750.