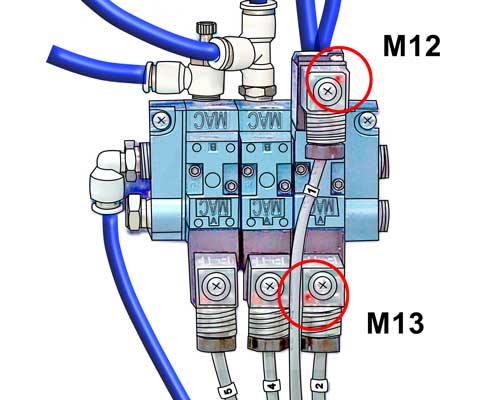

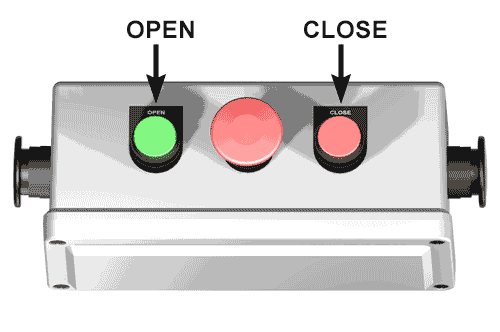

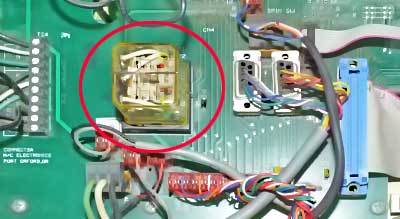

If the collet does not actuate reliably with the Palm Box, but the lights on the MAC valve light, the problem could be mechanical, either in the collet closer or the MAC valve.

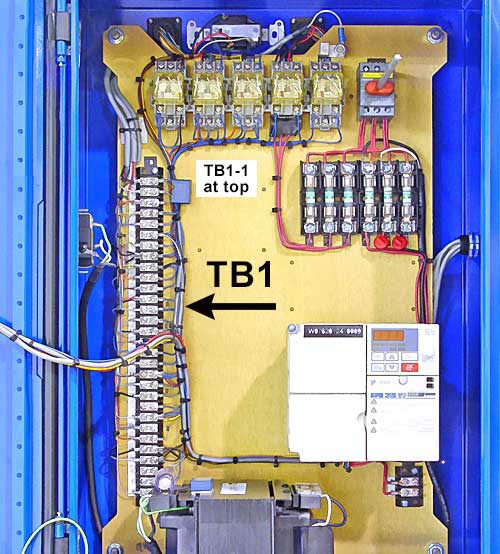

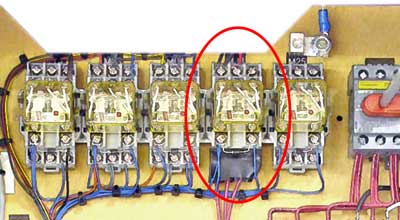

To verify that the voltage is good, open the spindle electronics cabinet and power up the machine.

With servos on, and DC voltmeter leads on TB1-12 and TB1-13, meter should read at least 11 volts when collet open button is pressed. Move leads to TB1-14 and TB1-15: meter should read at least 11 volts when collet close button is pressed.

If the voltages are correct, and the lights on the MAC valves light, but the collet doesn’t actuate, the issue could be mechanical.

If your voltage is over 10.5 volts but the collet closer doesn't operate, it could be a sticky valve, or the collet closer itself may be sticking. Verify that the collet closer is not stuck by loosening the thumbscrew that locks the drawtube, and turning the knurled knob so as to adjust the collet.