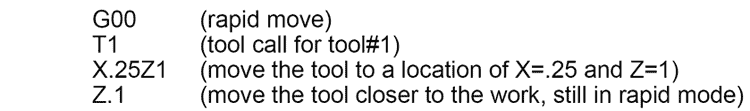

The first block of the T command must have a tool number in the range of 1 through 32. The slide does not move when this command is executed, but the position display will change to show the how far the tool being used is from the absolute zero of the part.

The second block of the T command must be an X and Z move. Both X and Z values must be declared. This is the location that the tool will move to.

To be safe, you should first move the tool to a location that is relatively far from the part in Z, and then move the tool into the work. This will help eliminate some of the tool interference problems new users encounter. Later you can call the tool closer in Z to shorten the cycle time.

In order to use a tool, the control must know where part X and Z zero are located. This is done in Jog mode by 'touching off' each tool that is used in a program.

Program fragment: