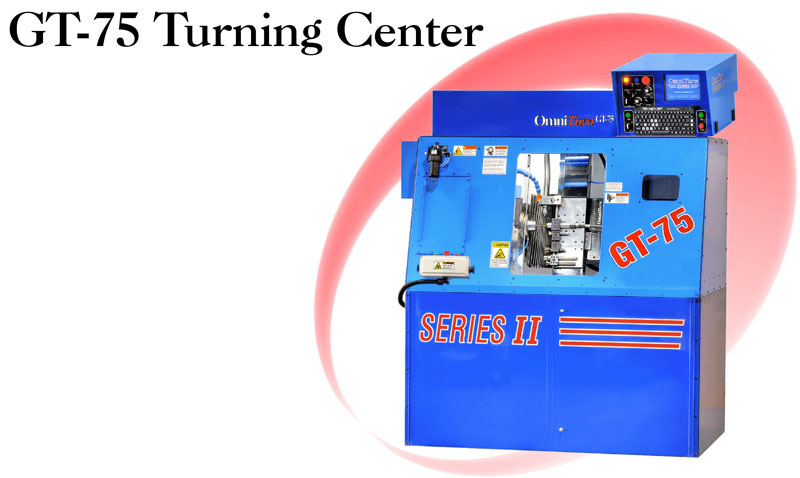

Gang-tooled for fastest tool changes.

75° slant-bed lets chips fall away quickly.

12” X-Axis travel; 9” Z-Axis travel.

Highest quality ground ball-screws and linear guides for precision and reliability.

Closed-loop servo system provides .0001” accuracy with .00005” resolution.

5hp spindle (C-Axis positioning optional)

4000rpm (5000 optional)

Barfeed ready.

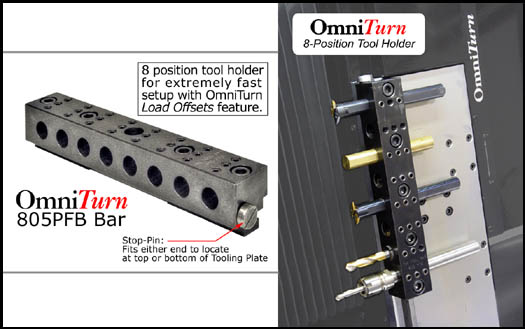

Gang-tooling is fast for repeat setups! OmniTurn’s “Save Offsets” feature lets you setup a complex repeat job in just minutes if you’ve saved your tooling in this 805PFB holder. Just re-locate the holder on the tooling plate and load your part program with offsets and you’re ready to run parts in minutes. No need to re-set all your tooling. The locating pin insures that the holder is back in place, and the original offsets load into the OmniTurn with the program.

The OmniTurn 805PFB (pictured above) is an 8-station tool-bar that accepts 5/8” tooling on 1.1” centers. Stop-pin fits either end so bar can be located on either side of OmniTurn tooling plate. OmniTurn “Save Offsets” feature instantly retrieves offsets when program is loaded, so repeat jobs can be re-set in minutes. Shown at right on OmniTurn GT table. Note that the steep 75° angle allows chips to fall away quickly into chip-pan.

Workholding . . . . . . . . . . . . . . . . . . . 5C Collet

. . . . . . . . . . . . . . . . . . . . . . 4” Chuck Max (opt.)

Max. Cutting Diameter . . . . . . . . . . . . . . . . . .6”

Max. Bar Diameter . . . . . . . . . . . . . . . . . . 1.06”

Tooling Plate . . . . . . . . 6” x 14” with 3/8” T-Slot

Max Speed . . . . . . . . . . . . . . . . . . . . 4,000rpm

Max Rating . . . . . . . . . . . . . . . . . . . . . . . . .5 hp

Spindle Nose . . . . . . . . . . . . . 5C w/4° camlock

Drawtube Bore . . . . . . . . . . . . . . . . . . . . 1.125”

Ways . . . . . . . . . . . . . . Precision Linear Guides

Ball Screws . . Precision-ground Zero Backlash

Base Billet . . . . . . . . . . MJ7 Composite Casting

Headstock . . . . . . . . . . . . . . . . . . . . . Mehanite

Coolant Pump . .1/8hp 5gpm (1/4hp 20gpm opt)

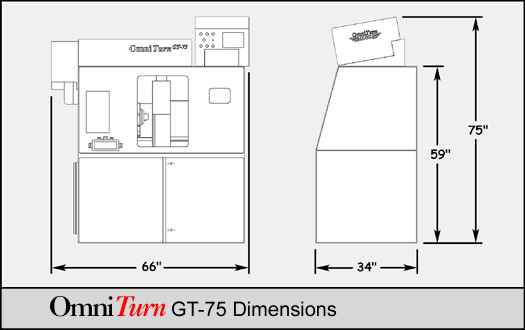

X-Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12”

Z-Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9”

Resolution of Slide Travel . . . . . . . . . . 0.00005”

Repeatability of Slide Travel . . . . . . . . . 0.0001”

Threading . . . . . . . . . . . . . . . 240tpi to unlimited

Axes Thrust . . . . . . . . . . 500lbs cont. 750lbs int.

Max Rapid . . . . . . . . . . . . . . . . . . . . . . . 300ipm

Max Cutting . . . . . . . . . . . . . . . . . . . . . . 300ipm

Machine Weight . . . . . . . . . . . . . . . . . . 1,650lbs

Air Required . . . . . . . . . . . . . . . 3 scfm @ 70 psi

Electrical . 208 - 240 VAC, 1 or 3 phase @ 20A

Floor Space . . . . . . . . . . . . . 34” x 66” (75” high)