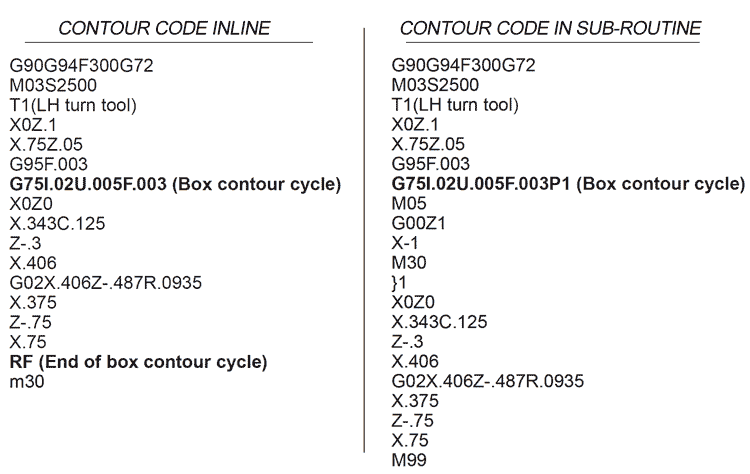

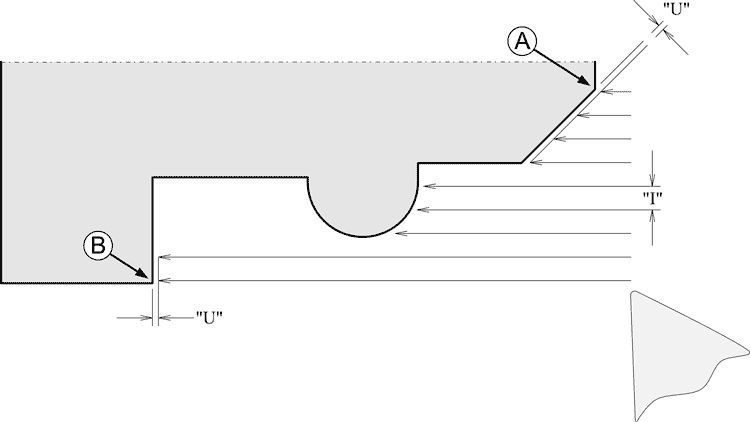

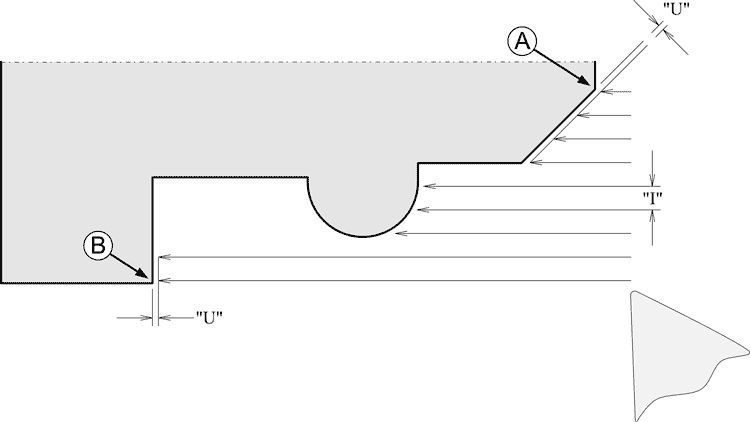

| In: | Maximum depth of cut per side per pass |

| Un: | The amount to be left on the part for the a finish pass |

| Fn: | The feedrate |

| Pn: | The subroutine number (optional) |

| RF: | If no subroutine, put RF at end of countour cycle |

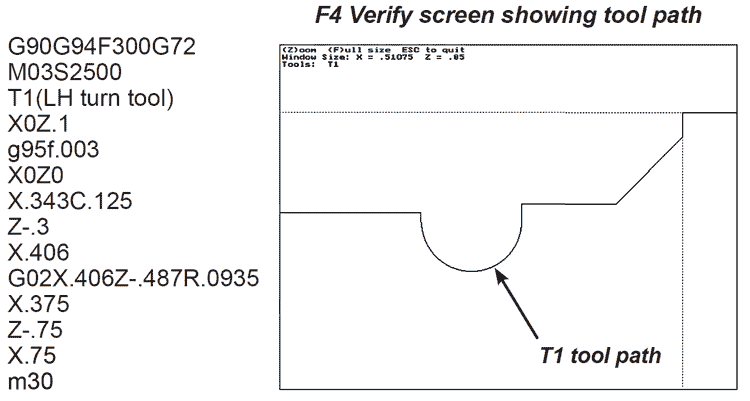

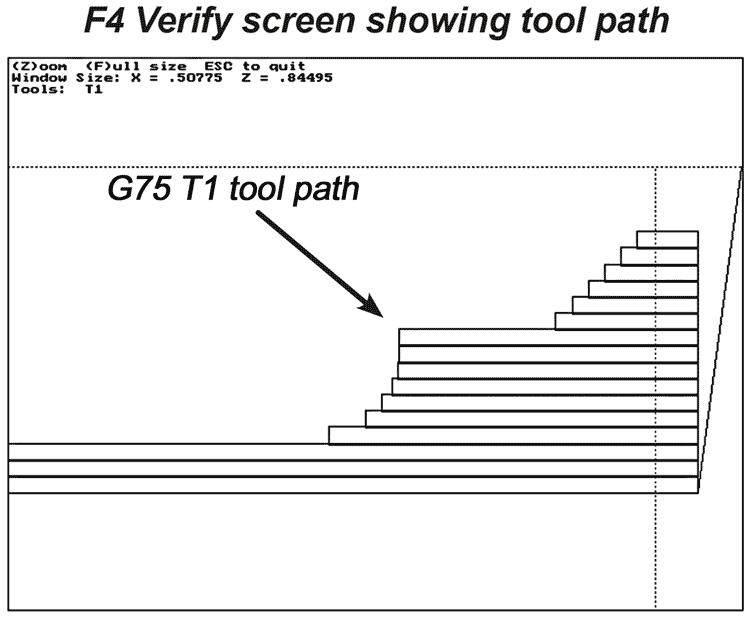

The box cycle starts at the current position, then makes cutting passes parallel to the Z axis at a cutting depth no greater than the I value until the last pass which is a U amount off the part.

The area of material that is removed is rounded by the Z and X axis through the tool start point and the contour from A to point B. At the end of the cycle, the tool is returned to the start point.

The location of the contour code: