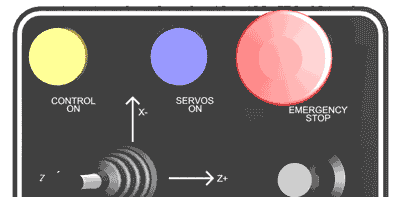

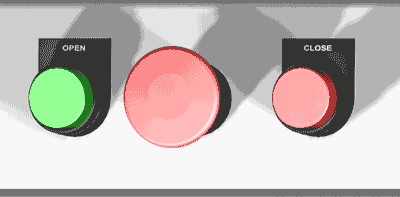

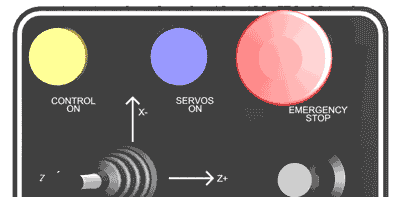

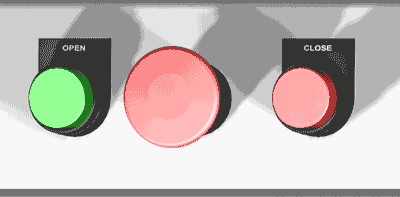

CNC Control Switches

Operator's Station

CNC Control Switches

Operator's Station

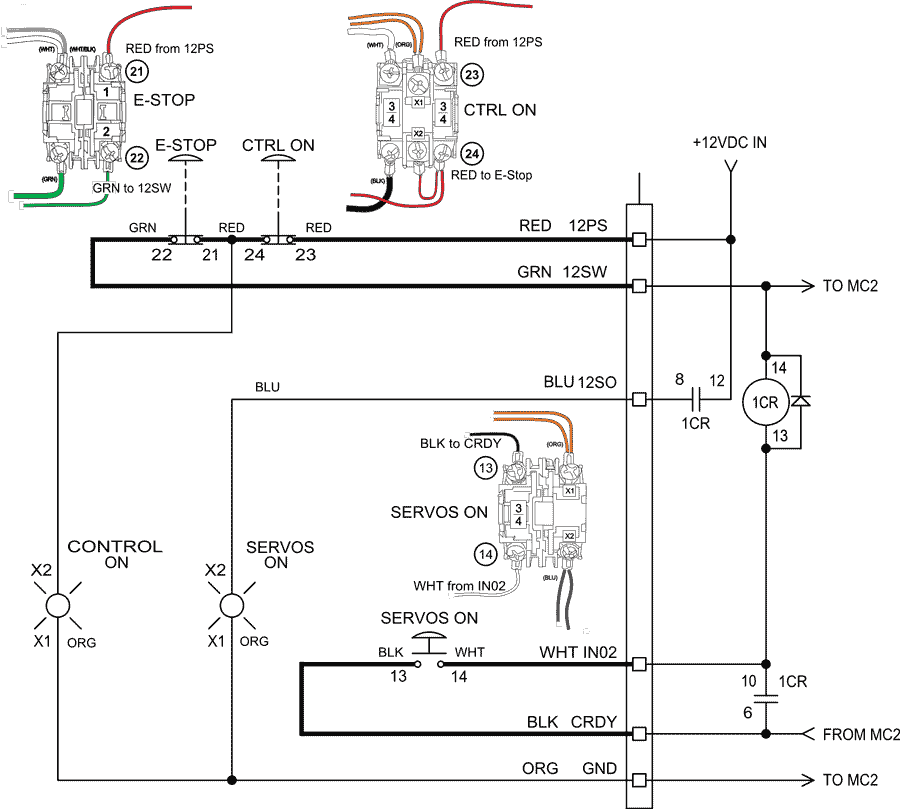

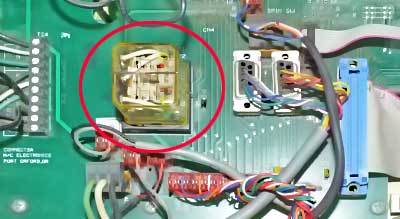

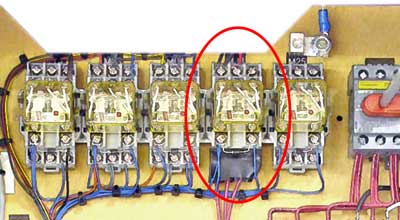

1CR (Servos Enable relay)

M08 (Coolant On relay)

If the E-Stop switches are disengaged, and and you’ve swapped 1CR with M08, but you still cannot turn on the servos, you will need a voltmeter to troubleshoot the problem.

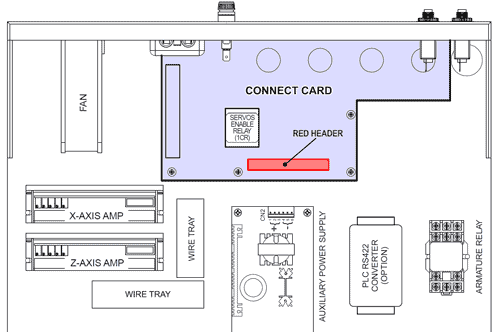

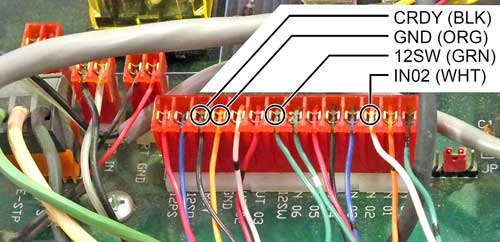

Remove the blue cover of the CNC and locate the red header connector on the Connect Card.

Measurements are taken at the “Turn Servos On” prompt.

G3 Connect Card

First verify E-Stop switches on CNC and on Palm Box (Operator’s Station) are dis-engaged; next, swap 1CR with M08 in spindle drive cabinet.

G3 Red Header

If the 12VDC is NOT present from GND to 12SW (#1 above), there is open circuit between 12PS and 12SW. See below for continuity testing.

If the 12VDC IS present from GND to 12SW (#1 above) but CRDY to 12SW is NOT about 11V (#2 above), the wide ribbon cable may not be connected properly, or the ribbon cable or connect card has a bad connection. It is much more likely to be a connection problem than a malfunction of the MC2 card, since if the card fails to initialize you don’t get the “Turn Servos On” prompt.

Unplug and replug the wide ribbon cable at both ends; examine both ends to insure that the wires are all seated firmly between connector body and top.

If the CRDY to 12SW is about 11V (#2 above), and GND to CRDY is about 1VDC (#3 above), there is an open connection in the wiring to the Servo On switch, or a bad contact on that switch.

To verify Servo On switch circuit, put black meter lead at GND and red lead at IN02; the meter should read about +12VDC. Press the Servos On button; the voltage should drop to about +1VDC.

See below for continuity testing.

UNPLUG THE CNC FROM THE POWER RECEPTACLE!

If the 12VDC is NOT present from GND to 12SW (#1 above), then there is open circuit between 12PS and 12SW. Refer to schematic below. The upper bold line, from 12PS to 12SW is the circuit you are checking.

UNPLUG THE CNC FROM THE POWER RECEPTACLE, press Ctrl On switch, dis-engage front panel E-stop, then use your continuity tester or ohm meter to check between following points:

The open circuit is wherever you didn’t get continuity

If CRDY to 12SW is about 11V (#2 above) but GND to IN02 stays at about +12VDC, there is open circuit between CRDY and IN02. Refer to schematic below. The lower bold line, from IN02 to CRDY is the circuit you are checking.

Use your continuity tester or ohm meter to check between the following points:

The open circuit is wherever you didn’t get continuity.