Measure DC Volts at Motor Terminals

If one axis doesn’t move, but you can see the position counter changing in Jog-1, the motor armature circuit might be open.

To quickly determine if the motor is bad, set servos off, disconnect both motor cables at back of control, and connect the bad axis motor cable to the good axis. Jog the good axis: if the bad axis moves, the motor is good and the issue is in the control.

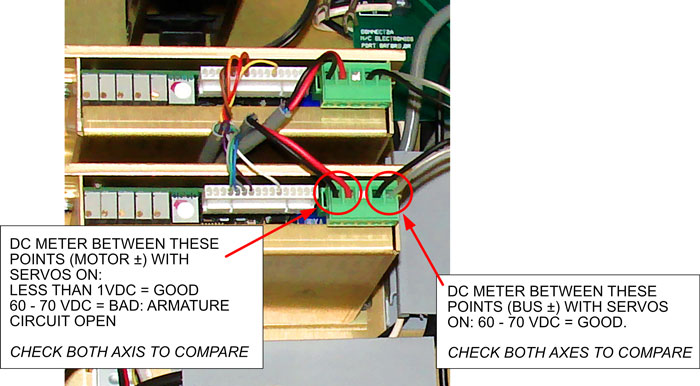

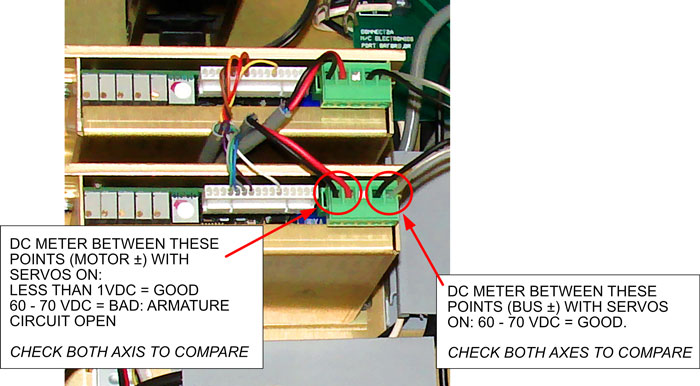

If the armature circuit is 'open', the motor terminals on the servo amp will be about the same as the bus voltage. Set servos off, reconnect motors and set servos on. Measure DC volts at motor terminals on the bad axis: if it is 60 to 70VDC, the armature circuit is open.

Measure DC Volts at Motor Terminals

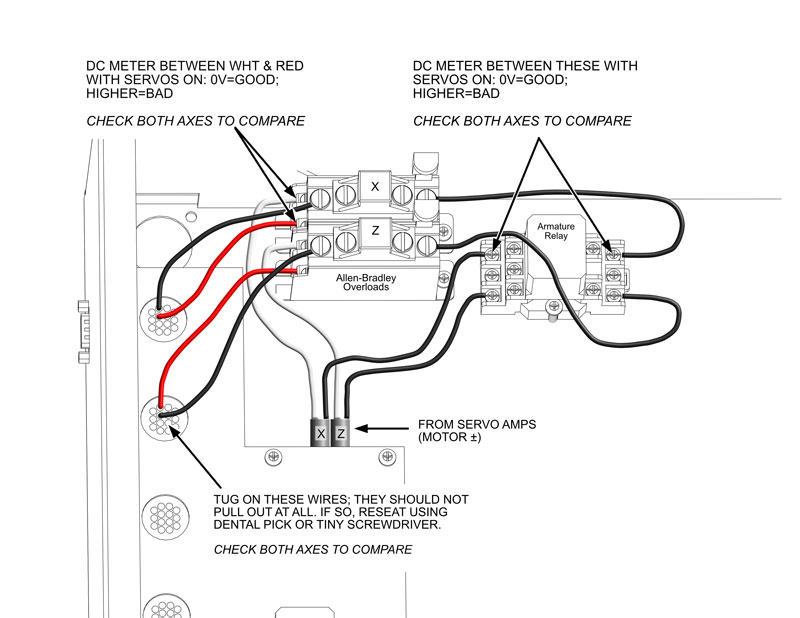

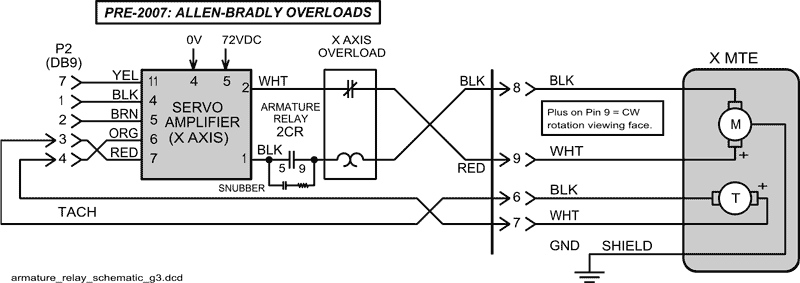

Early Servo Motor Armature Circuit

Early Armature Circuit Schematic

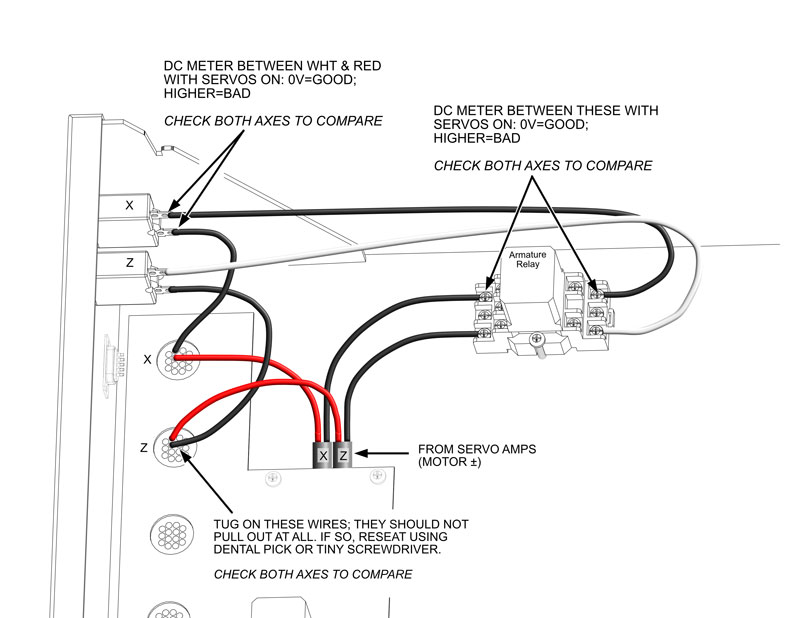

Later Servo Motor Armature Circuit

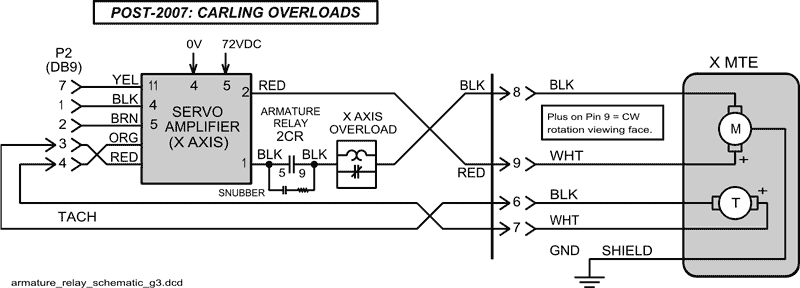

Later Armature Circuit Schematic