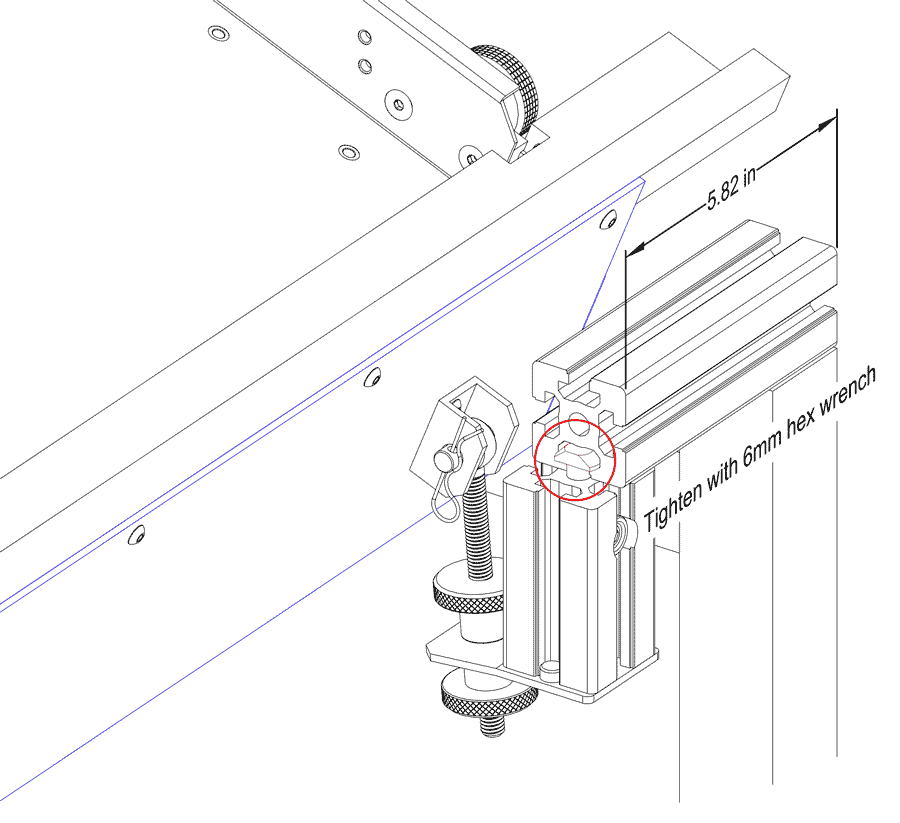

Micrometer Adjustment Installed

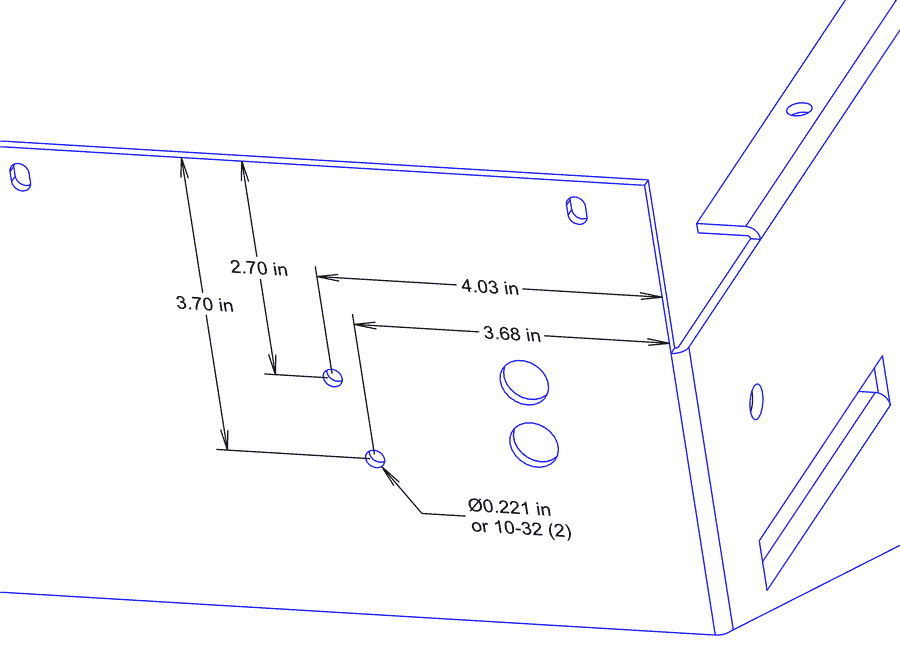

Drill two holes in the chassis assembly to accommodate the bracket. The micrometer assembly mounting screws include nuts, so you can either drill 0.221 through and use the nuts, or drill and tap 10-32.

Micrometer Adjustment Mounting Holes

The assembly attaches to the ZipLoader frame with a tee-nut that is tightened by a cam. Use 6mm hex wrench to tighten. Locate the assembly about 5.82 inches from the end, but do not tighten until the adjustment screw is mounted to the bracket to insure alignment.

Micrometer Adjustment Location (Cutaway)